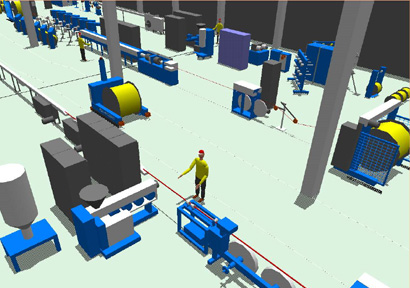

Nextrom's salesforce uses easy-to-use interface to configure a cable factory jointly with the client and to visualize an operating virtual factory using an integrated simulator (click on the graph for a full size view)

Nextrom Technologies

Visual configurator empowers Nextrom's salesforce

Nextrom is the world's leading supplier of manufacturing systems. To succeed, the company's sales force must be able to rapidly configure a complete cable factory to meet customer requirements. Working with Design Power and its Design++® technology, a Virtual Factory design system was created to enable:

- Rapid generation of accurate proposals

- Automated cable factory configuration

- Automated 3D visualization of factory configurations

- Automated simulation of manufacturing processes

Selling for Success

Cable manufacturing is an infrastructure support industry with global and distributed markets. Developing nations are building their infrastructure. This market demand coupled with the increasing need for telecommunications infrastructure in Europe and North-America is driving impressive growth in the cable industry.

Selling cable factories is highly consultative. Responding to customer requirements faster than the competition is critical to success. A salesperson must be able to configure a factory, to meet the customer's requirements, without having to wait for technical guidance from the home office. He must have access to knowledge about cable products and processes needed to manufacture them.

Nextrom envisioned a system that allows a sales person to configure a factory jointly with a customer. Together they specify product and production mix to drive the factory configuration. The system then simulates and visualizes the completed factory.

Realizing the Vision

Nextrom contracted Design Power Group (DPG) to make their vision a reality. A team of experts from Nextrom and DPG documented Nextrom's work processes, product composition rules, cable manufacturing processes and resources, etc. Together they developed a Virtual Factory Configuration System that achieved Nextrom's goals.It integrates with Nextrom's work processes, databases, Product Data Management system, and with a 3D virtual factory simulation tool.

Virtual Factory

Using the Virtual Factory Configuration System the cable factory configuration is initiated by defining the cable production and product mix. Designers import cable structures form databases or define and store them for reuse as needed. Using captured knowledge the system configures processes and their stages. These are matched to production lines, machines and equipment stored in a database. Designers can modify stages and production lines by joining and splitting them. This critical feature allows highly optimized factory designs.

Sampo Ahonen realized Nextrom's vision of empowering its sales force with a visual configurator using Design++® technology

The system creates a layout for the factory, builds a model and configures the control logic for 3D visual simulator. This timesaving step alone makes simulation feasible. The visual simulation shows the proposed cable factory fully operational. All events in the factory are observed in accelerated real time and in 3D. Bottlenecks are visually identified and eliminated to optimize the layout. All simulation events are recorded for further analyses. The system then produces a complete proposal ready for the customer's review. This allows designers, engineers and customers to work together to design and deploy cable factories faster, more efficiently and accurately than ever before.

Management Endorsement

Sampo Ahonen, Nextrom Project manager:

"We clearly have a significant advantage over our competitors, thanks to Design++. The system also enables us to enhance the services we deliver to customers. In addition, we are able to deliver these services much faster and more reliably."

The Team

This team of experts from Nextrom worked with Design++ to create a

visual sales automation tool.

Now Nextrom sales-engineers are leaving the competition behind.